Ⅰ. Energy-saving Chiller

Major Energy-saving business scope: energy-saving chiller system, Automatic Tube Cleaning System, Power Quality Solution.

1.Advantages

①Save Power 16~31%

②Save Water 45~50%

③Integrated System, compact structure, less space occupied

④Save manpower due to easy operation

2. Core Technology Description

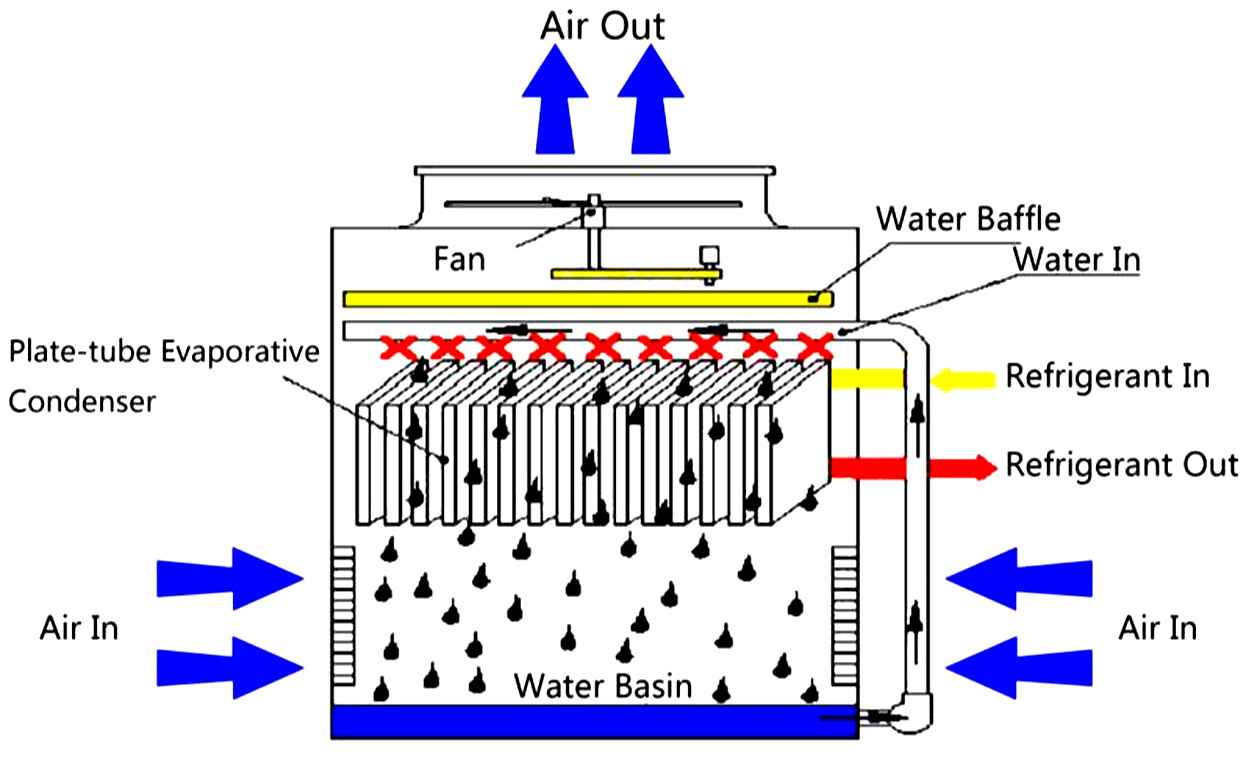

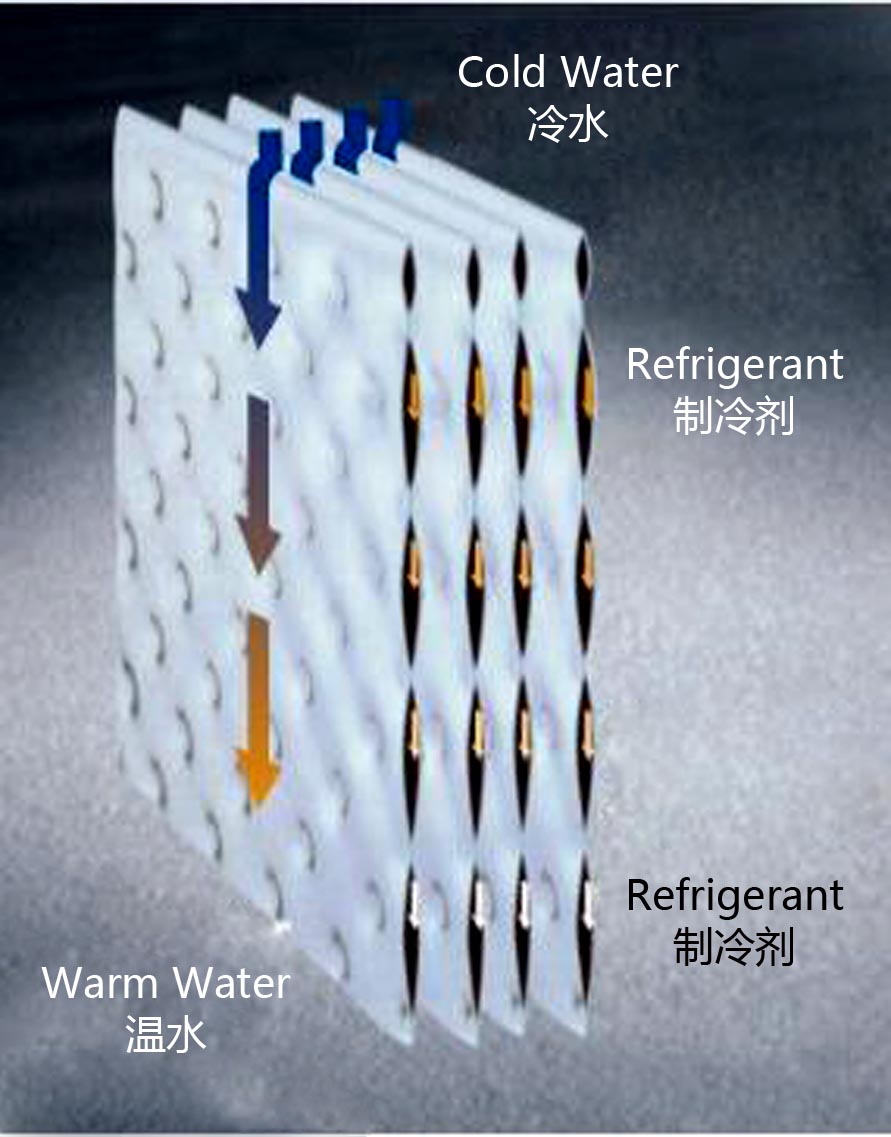

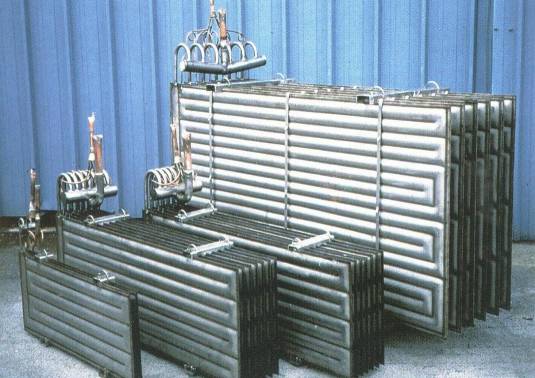

①. ETCO Plate-tube Evaporation-cooled Condenser Structure Theory

It integrates condenser and cooling tower into one system, therefore eliminate the process of cooling water from condenser to cooling tower. Instead, it take full advantages of water evaporation to improve heat exchange rate (latent heat), saving 45%~50% water and 16%~31% electricity.

② ETCO Plate-tube Evaporation-cooled Chiller Working Theory

Evaporative condenser takes water and air as cooling medium. Water evaporation takes away condensing heat. Water pump carries cooling water to condensing tubes; and then the upper nozzle sprays water evenly in the plate-tube outside surface, forming a very thin layer of water film. When high temperature gas refrigerant goes into the tube, the water film outside the tube absorbs heat and refrigerant becomes liquid flowing down to the water sink. After heat absorption, part of cooling water evaporates as gas, the rest part flow down to the water sink, which will be circularly used by water pump. The fan forces air to go through the plate-tube at the rate of 3-5 m/s to fasten water film evaporation, improving heat exchange rate.

③ETCO Innovation Water-film Evaporation Condensing Technology

Mature system integrated water-film technology makes sure the condenser is 100% covered by water film.

Anti-corrosion Titanium Alloy material, no water scale, no water splash.

| Type | Air-cooled | Water-cooled | Evaporative-cooled |

| Condensing Temp | 45℃ | 40℃ | 38℃ |

| Air Flow Rate | 420-500m^3/h | 120-200m^3/h | 110-160m^3/h |

| Cooling Water Pump Head | -- | >20m | 3-5m |

| Energy Consumed | 0.026KW | 0.038KW | 0.014KW |

| COP | 2.5-3.2 | 4.5-5.0 | 5.0-6.0 |

| Conclusion | Less electricity 31% |

Less electricity 16% Less water 50% |

3.Evaporative-cooled Condenser VS Water-cooled / Air-cooled Condenser

Ⅱ. Automatic Tube Cleaning System

Automatic Tube Cleaning System is designed to help central air-conditioning keep high efficiency. Generally, it saves around 10% power.

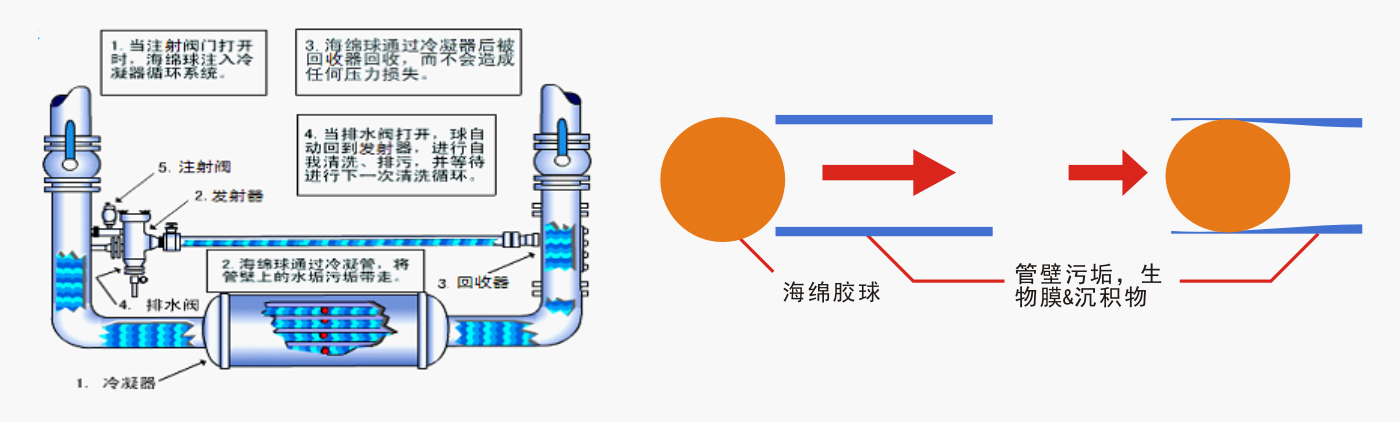

1. Automatic Tube Cleaning Theory

PLC control system periodically inject all of the balls into the inlet pip at the same time. Then normal system water flow carries the balls into the main pip, from where the balls enter into the condenser (heat exchanger). The balls randomly distribute to the condenser tubes. The ball flow through the tube at normal flow velocity. As the water pushes the ball, they clean off residue, deposit. When the ball comes out from the tube, they are collected to a special-designed ball trap and back to the ball collector. Then the collector holds the ball until the next cycle. 40 times/ day keeps the condenser continuously clean.

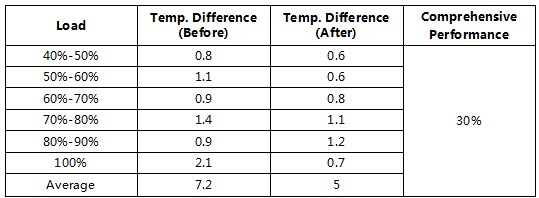

2. Performance Example